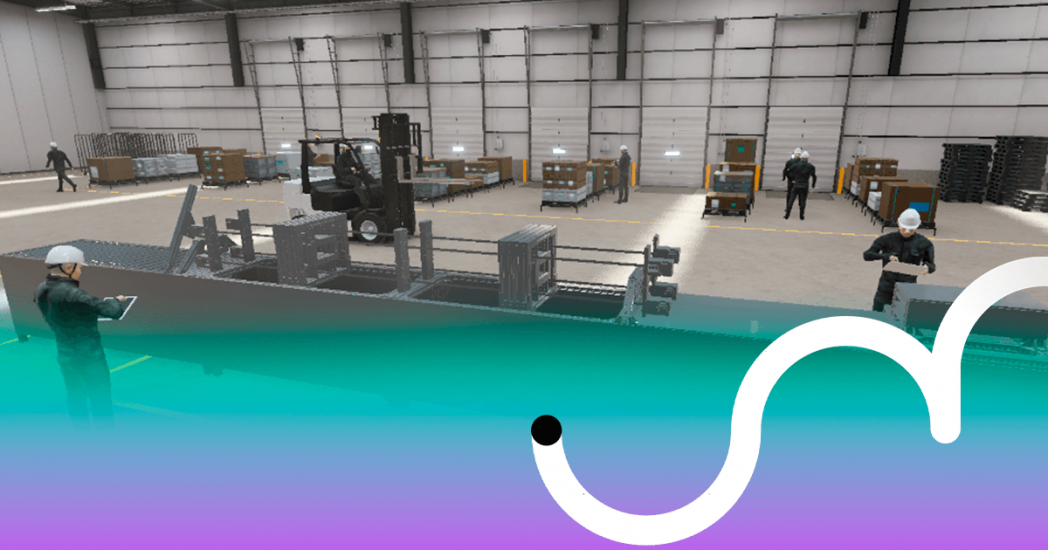

Technology was used to reproduce the Angelus Odonto industrial pultrusion process in a 3D virtual environment

The virtual representation of an object or production process, fed with constantly updated real-world information, allows simulations of changes and innovations capable of bringing productivity, performance or quality gains to an industry – without impacting its normal day-to-day activities. This is the main advantage of Digital Twin technology, which was applied in a proof of concept conducted by CPQD in the fiberglass post manufacturing process of Angelus Odonto, a dental products manufacturer based in Londrina, Paraná.

The proof of concept (PoC) is part of the second phase of the Data Intelligence Platform – Digital Twin project, developed by CPQD with funding from the Softex Priority Innovation Program (PPI). The focus of the PoC was the creation of a digital twin of the industrial process called pultrusion – an automated process for manufacturing fiber-reinforced plastic profiles. In this specific case, the digital twin reproduced the pultrusion process with fiberglass and resin, used at Angelus to manufacture dental pins.

CPQD Website

“Factors such as temperature, humidity, fiber thickness, resin quality, among others, can affect the quality of the final product obtained through pultrusion. Furthermore, creating new pultrusion lines requires a large financial investment,” explains Marcio Funes, systems architect at CPQD. “In this context, the use of a digital twin that simulates new pultrusion lines and shows how the environment can affect product quality brings great benefits to the industry,” he adds.

To this end, the CPQD team used advanced three-dimensional modeling techniques to faithfully reproduce the real environment in the virtual world, with all the features and equipment involved in the Angelus pultrusion process – including conveyors, forklifts, pultrusion machines, etc. To collect and integrate the data generated during this process in the real world, CPQD's Pailot platform was used, which combines Internet of Things (IoT) and Artificial Intelligence (AI) resources.

“With Pailot, it was possible to collect data from sensors located in the pultrusion machine in real operation, such as temperature, humidity, thickness and tension of the fiber produced, for visualization, management and analysis in the virtual environment. This integration was very important to feed the digital twin with updated and accurate information about the pultrusion process, from which several simulations can be carried out”, highlights Norberto Alves Ferreira, AI and IoT Solutions Manager at CPQD.

According to him, the digital twin developed during the PoC demonstrated high precision in representing the 3D model of the pultrusion machine and the pultrusion process itself, under different operating conditions. “This precision in the environment is important, especially in simulations of positioning new pultrusion lines and assessing the impacts of external factors, such as temperature and humidity, on the quality of the final product. In addition to allowing a detailed view of this process in the virtual world, the digital twin paves the way for the future development of preventive maintenance strategies, performance optimization and other improvements within the industrial environment”, concludes Ferreira.